Global Best Practices for improving coolant efficiencies

Instructions for Optimal Use of passive Coolants (Gel ice pack) for 2-8 degree centigrade products

- Coolants to be pre-conditioned at -14 degree Celsius (Hard Freeze) for 24 hours prior to use. These are ‘passive’ products and need to be conditioned suitably

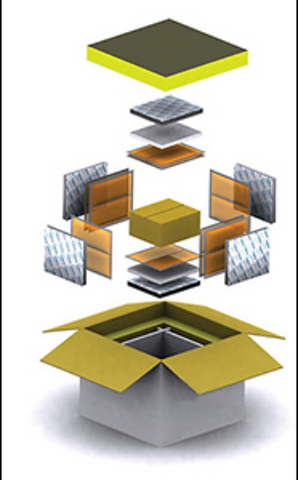

- Please ensure that packing of material is done in cold room condition, frozen refrigerants should be placed around products to absorb the heat that may enter from any direction, typically at the bottom, sides and top. Surround all six sides of your product with gel packs, avoid leaving empty spaces in the box, fill up with paper or allied material as the air in the empty spaces tend to heat up making the coolants less effective. Seal the box securely to minimize heat exchange

- Quantity of passive coolants to be used is generally determined by the size and weight of the product. Depending on the season, destination and the duration of the shipment, quantity of refrigerants may need to be determined. It is recommended that you conduct tests to determine the quantity of refrigerant to meet your requirements

- We would advise that a product-to-passive coolant weight ratio of 1:2 or 1:1 depending on the be maintained, though as mentioned earlier, depending on the season and country, more coolants maybe required than the ratio would dictate